Engineering plastics are an integral part of many industries, from automotive to healthcare. They offer excellent durability, chemical resistance and thermal stability. PVC is a popular engineering plastic used in a variety of applications. This article will provide an overview of the characteristics and uses of PVC as an engineering plastic, including its advantages and disadvantages compared to other materials. It will also explore potential areas of innovation in the use of PVC as an engineering plastic.

What is PVC?

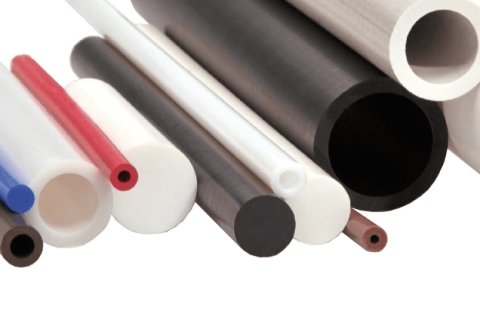

PVC or polyvinyl chloride is a synthetic plastic polymer that is widely used in various industries due to its versatility, durability, and cost-effectiveness. It is commonly used in the construction industry for pipes, siding, window frames, and roofing materials. PVC can also be found in medical devices such as tubing and blood bags due to its biocompatibility.

In terms of engineering plastics, PVC falls under the category of thermoplastics. Thermoplastics are plastics that can be melted and molded repeatedly without losing their properties. However, compared to other engineering plastics like polycarbonate or nylon, PVC has lower strength and heat resistance properties.

Despite this limitation, PVC’s ease of processing makes it an attractive choice for many applications. Additionally, its low cost allows for mass production without breaking the bank. Overall, PVC’s unique combination of properties makes it a valuable material in various industries despite not being as strong as other engineering plastics on the market.

Properties of PVC

PVC, or polyvinyl chloride, is considered an engineering plastic due to its high strength and durability. It’s a thermoplastic material that can be easily molded into various shapes and sizes. PVC has excellent chemical resistance, making it popular for use in pipes, fittings, and other applications where harsh chemicals are present. Additionally, it has good electrical insulation properties and can withstand high voltage.

One of the most significant advantages of PVC is its cost-effectiveness compared to other engineering plastics like polycarbonate or nylon. It’s also lightweight and easy to handle during installation. However, it does have some limitations; PVC is susceptible to degradation under UV light exposure and may become brittle over time.

Overall, PVC has numerous desirable properties that make it useful in several industries such as construction, automotive manufacturing, electronics packaging among others. Its versatility makes it a popular choice for engineers looking for a durable yet affordable solution without compromising on quality.

Applications of PVC

Polyvinyl chloride (PVC) is a versatile and widely used thermoplastic material that has found its way into many applications across various industries. While PVC is not technically considered an engineering plastic, it does possess specific traits that make it suitable for use in certain engineering applications. With its excellent chemical resistance, electrical insulation properties, and durability, PVC is often used in the construction industry for pipes, fittings, and roofing materials.

Another common application of PVC is in the manufacturing of inflatable products such as pool toys or air mattresses. Its flexibility and ability to withstand high pressure make it an ideal material for these types of products. Additionally, PVC can be easily molded into different shapes and sizes making it a popular choice for creating custom products.

In conclusion, while PVC may not be classified as an engineering plastic per se, its unique properties have made it a valuable material for numerous applications across many industries. From construction to manufacturing to consumer goods – this versatile thermoplastic has proven time and again that its uses are limited only by our imaginations!

Advantages of Using PVC

PVC, or polyvinyl chloride, is a popular thermoplastic polymer that is widely used in many industries. It belongs to the family of engineering plastics and has several advantages over other materials. One of the primary benefits of using PVC is its high durability and resistance to wear and tear. PVC can withstand harsh environmental conditions, making it an ideal material for outdoor applications such as windows, doors, pipes, and roofing.

Another advantage of using PVC is its excellent chemical resistance. It can resist a wide range of chemicals, including acids and alkalines, making it suitable for use in chemical processing plants and laboratories. Moreover, PVC is a low-cost material that offers high value for money. It is easy to process and requires minimal maintenance compared to other materials such as wood or metal.

In conclusion, PVC’s unique properties make it an attractive choice for various applications across industries such as construction, automotive manufacturing, healthcare products manufacture among others. Its versatility makes it the preferred material by many engineers who require strength coupled with flexibility in their final product design without compromising on quality or cost-effectiveness.

Disadvantages of Using PVC

Yes, PVC or polyvinyl chloride is an engineering plastic that has been used in a wide range of applications. However, while it has its advantages, there are also several notable disadvantages to using PVC.

Firstly, PVC is not biodegradable and can persist in the environment for years. This means that disposal of PVC products requires special handling procedures and can contribute to environmental pollution if not done correctly. Additionally, the production of PVC releases toxic chemicals into the atmosphere, which can have negative effects on human health.

Secondly, because of its low melting point, PVC is not suitable for high-temperature applications such as those involving hot liquids or gases. It also tends to become brittle over time when exposed to sunlight and UV radiation.

Finally, some studies suggest that prolonged exposure to PVC products may have adverse health effects. For example, phthalates used to soften PVC have been linked to developmental issues in children and reproductive problems in adults.

Overall, while PVC has many useful properties that make it an attractive material for use in various industries and applications; however its disadvantages cannot be ignored either.

Alternatives to PVC

PVC, or polyvinyl chloride, is a widely used plastic in various industries due to its low cost and versatile properties. However, concerns have been raised over the environmental impact of PVC production and disposal, particularly due to the release of toxic chemicals during manufacturing and incineration. As such, many companies are exploring alternatives to PVC for their products.

One alternative to PVC is PET (polyethylene terephthalate) which is commonly used in food packaging and textile applications. PET has a lower environmental impact than PVC as it can be recycled multiple times without losing its quality or purity. In addition, it does not contain chlorine which is one of the main factors contributing to the harmful effects of PVC.

Another option is biodegradable plastics made from renewable resources such as corn starch or cellulose. These materials break down naturally when exposed to moisture and bacteria, reducing their impact on the environment compared to traditional plastics like PVC that can take hundreds of years to degrade. Biodegradable plastics can also be produced with similar properties as PVC making them an attractive alternative for many applications.

Is PVC an Engineering Plastic?

PVC, also known as polyvinyl chloride, is a frequently used plastic that has several applications in the engineering industry. It is commonly used in construction and other industrial applications due to its durability and resistance to weathering, chemicals, and abrasion. However, whether PVC can be classified as an engineering plastic is a topic of debate.

Engineering plastics are defined as materials with superior mechanical properties that can withstand high levels of stress without deforming or breaking. They are used in demanding applications such as automotive parts, electronics components, medical devices, and industrial machinery. While PVC does possess some desirable mechanical properties such as high tensile strength and low thermal conductivity, it falls short compared to other materials like polycarbonate and nylon when it comes to high-performance applications.

Despite its limitations, PVC remains an important material in the engineering industry for certain applications where its unique properties make it the ideal choice. As such, while not strictly considered an engineering plastic by some experts due to its incomplete range of characteristics required for this classification; it still plays a crucial role in many industries thanks to its versatility and cost-effectiveness.